Testing

The majority of the requirements are to quantify the quality of the medallions. The tests are to measure the variation between the two manufacturing methods, as well as the variation within each.

Circularity

The variation in the radial distance from the center of the piece.

As expected the machined medallions were consistent in circularity due to the nature of the processes. As for the casted medallions, the circularity was less than desired. The flash and runner, that was removed with a band-saw, contributed to the distortion of the circularity.

Shrinkage

Two methods were used to calculate the possible starting dimensions to compensate for shrinkage that occurs when the metal cools from a liquid to a solid. The mathematical method that ignored the volume loss due to the lettering, A8, predicted the correct value. The shrinkage for the outer diameter was measured to be 20 thousands, or .6% of the original 3.5 inches. The SolidWorks method (A9) of uniformly scaling each feature until the volume of the model increased by 6%. This method would have over sized the part.

SolidCast

The simulation software can provide a variety of information on what can be expected during a pour.

The most important information provided is the temperature throughout the mold. The temperature indicates the locations of the mold that will solidify first, and any shrinkage can be interpolated.

Video of the SolidCast simulation

The model and the gating system is constructed and then the flask is created around the mold.

Video of the SolidCast results

The results viewer showing the temperature over time.

Video of the SolidCast results

The results viewer showing solidification of the model.

Prediction of Aluminum Used

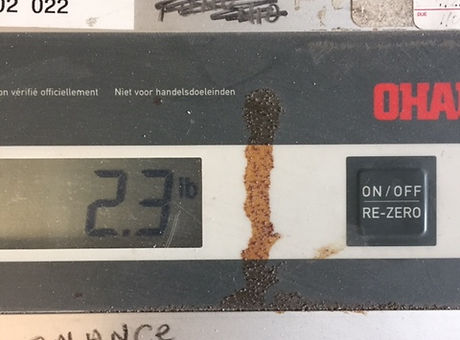

The volume needed per pour was predicted to be 27.21 inches cubed. With the assumption that the density would be .098 lb/in^3 the total weight of aluminum needed was 2.67 lbs. The actual weight of the six medallions and gating system weighed 2.3 lbs. The percent error of the two values is 13.8%

Tailings

The gating system weighed 1.0 lbs out of the total 2.3 lbs. The percentage of tailing is 43%. The smaller the percentage, the less waste is created, less energy and time used to melt the aluminum. 5-10% of the tailings are typically recycled in a commercial pour.